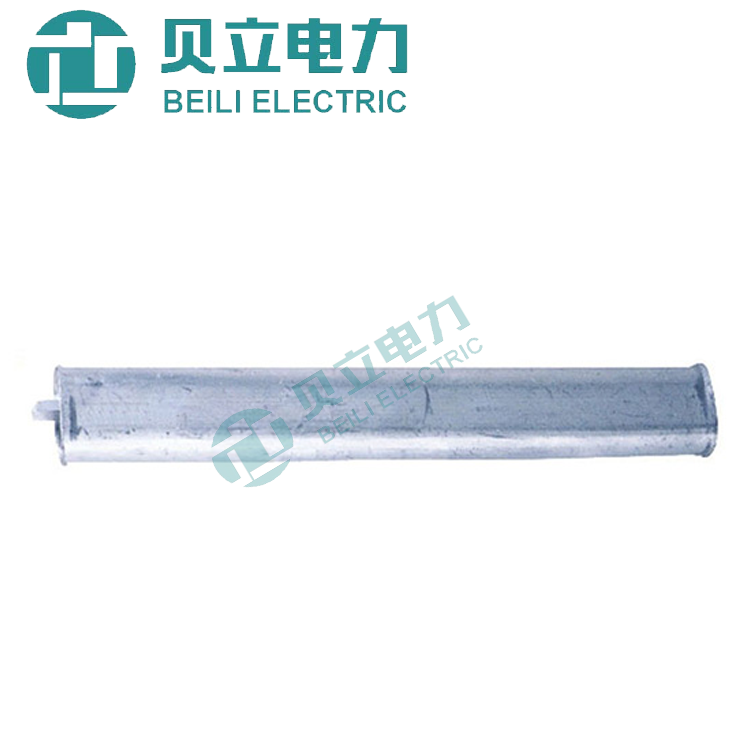

I-JJE Series C Uhlobo lweClamp yeTransformer

Inkcazo:

I-C-clamp ye-transformer yenziwe nge-alloy ekhethekileyo ye-aluminium, enezixhobo ezinamandla zokuqhuba, kwaye ifanelekile kubo bobabini abaqhubi bezobhedu kunye nabaqhubi benguqu yobhedu-aluminium.Esi sigqubuthelo sisetyenziselwa ukudibanisa kunye nokuqhawula i-studs kunye neengcingo ezivela kwii-transformers, iiswitshi kunye nezinye izixhobo.

Esinye isiphelo asivalwanga ngokupheleleyo kunye nesithuba se-threaded yangaphakathi edibeneyo, kwaye esinye isiphelo sidibene nocingo.Ibloko enehenjisi idibanisa umbhobho ojikelezileyo othungelwe ngaphakathi ngocingo.Umbhobho ojikelezileyo ovaliweyo ngokuyinxenye une-elasticity kwaye unokugcina kwaye ukhulule ucingo kunye ne-stud.Amandla abangelwa ukwanda kwe-thermal kunye nokunciphisa

Xa umthwalo ukhula, umqobo we-thermal we-wire wandisa, kwaye ityhubhu edibeneyo iya kuhlanjululwa kancane.Xa ucingo lubanjwe, ityhubhu edibeneyo ihoxiswa ngenxa ye-elasticity yayo, kwaye uxinzelelo oluhlala luhlala lugcinwa (i-co-breathing effect).

Ibloko yehinge efakwe phakathi kwetyhubhu ephothiweyo kunye nocingo inokuvelisa uxinzelelo oluphezulu kakhulu lwecala phantsi kwesenzo esithile, ukuze i-C-type clamp kunye nocingo, kunye noxinzelelo olwaneleyo loqhagamshelwano kunye ne-transformer kunye ne-stud, ukwenzela ukuba i-transformer. Screw Ikholamu ihambelana ngokupheleleyo netyhubhu edibeneyo yangaphakathi, eyandisa kakhulu indawo yoqhagamshelwano phakathi kwe-transformer stud kunye ne-C-clamp, kwaye igcina ukusebenza koqhagamshelwano oluzinzileyo.

Inqanaba lombane elisebenzayo: 380v, 10kV, 110kV, 220kV, 330kV, ingasetyenziselwa ukudibanisa intloko ye-aluminiyam kucingo lwe-aluminiyam, intloko ye-aluminiyam ukuya kucingo lobhedu, intloko ye-aluminiyam ukuya kwi-aluminium yocingo.

Iimbonakalo:

1. Ukuphefumla ngeengcingo kunye nesikhokelo, susa ukungaphumeleli kokuphuma kwe-thermal yocingo kunye noqhagamshelo lwezixhobo.

2. Ukunciphisa ngokufanelekileyo ukulahleka koqhagamshelwano

3. Ukunciphisa kakhulu ilahleko enkulu yezixhobo kunye nokuphuma kombane okubangelwa kukusilela kwe-thermal

4. Ukufakela kulula kakhulu, ngokukhawuleza kwaye kunciphisa kakhulu izinto zabantu

5. Ukugcinwa okungahlawulelwayo kunye nokugcinwa simahla ukuphucula ukusebenza kakuhle kotyalo-mali

6. Akukho zixhobo zikhethekileyo ezifunekayo, ezinokuphucula inzuzo yotyalo-mali

7. Ukwandisa kakhulu indawo yoqhagamshelwano phakathi kwezixhobo kunye neengcingo, ukuphucula ubomi benkonzo

8. Ixesha elide elithembekileyo kunye nokusebenza okukhuselekileyo kwemigca ye-bit kunye nezixhobo zibonelela ngesiqinisekiso esinamandla

| Umzekelo | I-Stud esebenzayo | I-Conductor esebenzayo | Ububanzi bocingo | Umzekelo | I-Stud esebenzayo | I-Conductor esebenzayo | Ububanzi bocingo |

| SP-B50 | M12 | I-LJ (TJ) 25 | 6.36 | SP-B94 | M20 | LJ (TJ) 150 | 15.75 |

| SP-B51 | M12 | JKLYJ35 | 7 | LGJ120 | 17.74 | ||

| I-LJ (TJ) 35 | 7.5 | SP-B95 | M20 | LJ (TJ) 120 | 14.25 | ||

| LGJ35 | 8.16 | LGJ95 | 13.6 | ||||

| SP-B52 | M12 | JKLYJ50 | 8.3 | SP-B71 | M16 | I-LJ (TJ) 35 | 7.5 |

| I-LJ (TJ) 50 | 9 | LGJ35 | 8.16 | ||||

| LGJ50 | 9.6 | I-LJ (TJ) 50 | 9 | ||||

| SP-B53 | M12 | JKLYJ70 | 10 | SP-B72 | M16 | LGJ70 | 11.4 |

| I-LJ (TJ) 70 | 10.8 | I-LJ (TJ) 70 | 10.8 | ||||

| LGJ70 | 11.4 | JKLYJ70 | 10 | ||||

| SP-B54 | M12 | I-LJ (TJ) 95 | 12.12 | LGJ50 | 9.6 | ||

| LJ (TJ) 120 | 14.25 | SP-B73 | M16 | I-LJ (TJ) 95 | 12.12 | ||

| SP-B55 | M12 | LJ (TJ) 150 | 15.75 | LGJ95 | 13.6 | ||

| JKLYJ185 | 16.2 | LJ (TJ) 120 | 14.25 | ||||

| LJ (TJ) 185 | 17.5 | SP-B74 | M16 | LJ (TJ) 150 | 15.75 | ||

| SP-B56 | M12 | LJ (TJ) 240 | 20 | LGJ120 | 15.74 | ||

| SP-B61 | M14 | I-LJ (TJ) 35 | 7.5 | SP-B75 | M16 | LJ (TJ) 185 | 17.5 |

| LGJ35 | 8.16 | LJ (TJ) 150 | 17.1 | ||||

| I-LJ (TJ) 50 | 9 | JKLYJ185 | 16.2 | ||||

| SP-B62 | M14 | LGJ70 | 11.4 | SP-B76 | M16 | LGJ185 | 18.9 |

| I-LJ (TJ) 70 | 10.8 | JKLYJ240 | 18.4 | ||||

| JKLYJ70 | 10 | SP-B77 | M16 | LJ (TJ) 240 | 20 | ||

| SP-B63 | M14 | LGJ50 | 9.6 | SP-B81 | M18 | I-LJ (TJ) 35 | 7.5 |

| I-LJ (TJ) 95 | 12.12 | LGJ35 | 8.16 | ||||

| LGJ95 | 13.6 | I-LJ (TJ) 50 | 9 | ||||

| LJ (TJ) 120 | 14.25 | SP-B82 | M18 | LGJ70 | 11.4 | ||

| I-SP-B64 | M14 | LGJ120 | 15.74 | I-LJ (TJ) 70 | 10.8 | ||

| LJ (TJ) 150 | 15.75 | JKLYJ70 | 10 | ||||

| SP-B65 | M14 | LGJ150 | 17.1 | SP-B83 | M18 | LJ (TJ) 120 | 14.25 |

| LJ (TJ) 185 | 17.5 | LGJ95 | 13.6 | ||||

| I-SP-B66 | M14 | LGJ185 | 18.9 | I-LJ (TJ) 95 | 12.12 | ||

| JKLYJ240 | 18.4 | SP-B84 | M18 | LJ (TJ) 150 | 17.75 | ||

| SP-B67 | M14 | LJ (TJ) 240 | 20 | LGJ120 | 17.74 | ||

| SP-B91 | M20 | LJ (TJ) 240 | 20 | SP-B85 | M18 | LJ (TJ) 185 | 17.5 |

| SP-B92 | M20 | LGJ185 | 18.9 | LGJ150 | 17.1 | ||

| JKLYJ240 | 18.4 | JKLYJ185 | 16.2 | ||||

| SP-B93 | M20 | LJ (TJ) 185 | 17.5 | SP-B86 | M18 | LGJ185 | 18.9 |

| LGJ150 | 17.1 | JKLYJ240 | 18.4 | ||||

| JKLYJ185 | 16.2 | SP-B87 | M18 | LJ (TJ) 240 | 20 |

Ukuhlohla:

1. Qinisekisa imodeli: Khangela ngononophelo ukuba ngaba ucingo luyahambelana nemodeli ephawulwe kwi-clamp, njenge: Imodeli ZJC-B51, i-M12 ithetha ukuba i-screw ye-transformer ye-lead yi-M12, kunye ne-JKLJ35 yintambo ephumayo.

2.Lungisa "g" -shaped element: screw it clockwise kwi-screw ye-transformer, kunye ne-"g" -shaped element inokujijwa kwaye yandiswe ngaphandle.Izibonelelo: Ibhloko yabasetyhini ihambelana necala le-arc ye-transformer, ibhloko yendoda ihambelana nocingo, kwaye ibhloko ye-hinge ikhutshwe ukuze iyenze (iibhloko ezimbini ze-hinge ziguqulwa zibe yi-angle ethile)

3. Beka iingcingo kunye neebholithi endaweni: Faka iingcingo kwi-"g"-shaped grooves, kwaye uzibeke kumdibaniso we-hinge owenziwe ngesaphetha ngokwe-arc surface.Ungafaka iibholiti ngasemva ukwenzela ukuba iibholithi zibe kwindawo ephakathi kumphezulu weehenjisi.Qinisa iibholithi ngesikrufu.)

4. Qinisekisa ukuba ifakwe ngokufanelekileyo: Xa uqinisa i-bolt, iintambo ezimbalwa zokugqibela kufuneka zibe nokuqonda okucacileyo kwamandla.Cinezela i-hinge clamp kwaye ucinezele ngokuchasene ne-"g" -shaped element.Into ethi "g" kufuneka ikhubazeke kancinane.(Emva kokufakela, tsala ucingo kwaye ulukhuphe ngokutsala okanye ulutsale ukuze ubone ukuba ucingo kunye nokutsalwa ziqinile)

5. I-Disassembly: Khulula iibholiti, faka i-screwdriver phakathi kwebhloko yokucofa kunye ne-"C" element, kwaye ucofe ngamandla ukuze uguqule ibhloko yokucinezela phezulu.